ABAQUS, A PROVEN SIMULATION SOLUTION

Traditional design and development involve physical testing and trial-and-error loops to achieve a satisfactory product. Today, digital simulation makes it possible to reduce these costly and time-consuming tests to a minimum by evaluating the impact of changes on the objective pursued: a lighter material can help to reduce the mass but is not necessarily capable of withstanding the same level of stress.

And where is this maximum stress? When the design or the loads are complex, numerical simulation is the only way to answer. Experience can help, but it can also give you the wrong impression, especially when you change materials: the forces do not propagate at all in the same way in a composite as in a metal, and this can be seen with numerical simulation.

With the right model, numerical simulation can predict the behavior of the new design. However, not all software is equal.

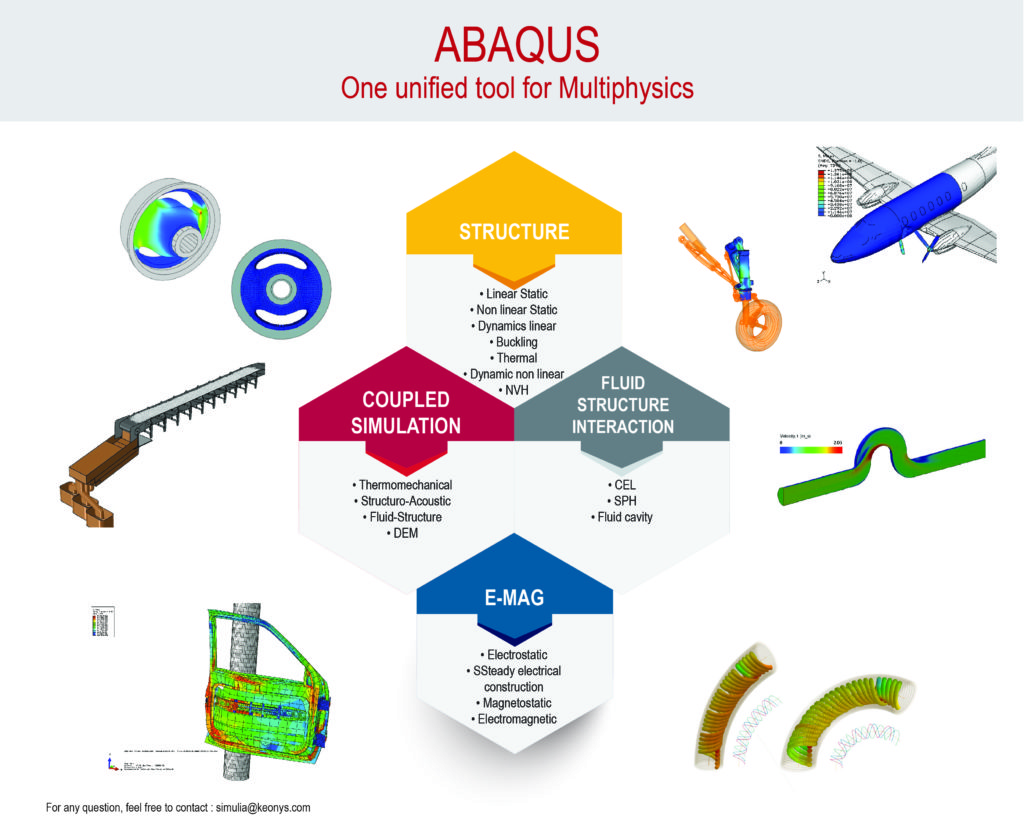

ABAQUS stands out for its ability to handle multiphysics problems in a realistic way, in particular by relying on 4 recognised strengths:

- Contact processing, which is particularly easy to use and robust,

- The modelling of numerous material behaviors, which enables to address industrial issues:

– Plasticity and fracture of metals,

– Hyperelasticity of elastomers,

– High compressibility of foams,

– Porosity of geotechnical materials (soils, rocks…),

– Compressibility of fluids,

– Electrical conductivity,

– …

- The ability to deal with problems from static to fast dynamic thanks to adapted and included methods in the solution,

- Multiphysics coupling via fully integrated procedures and openings to other calculation codes.

INTERFACE

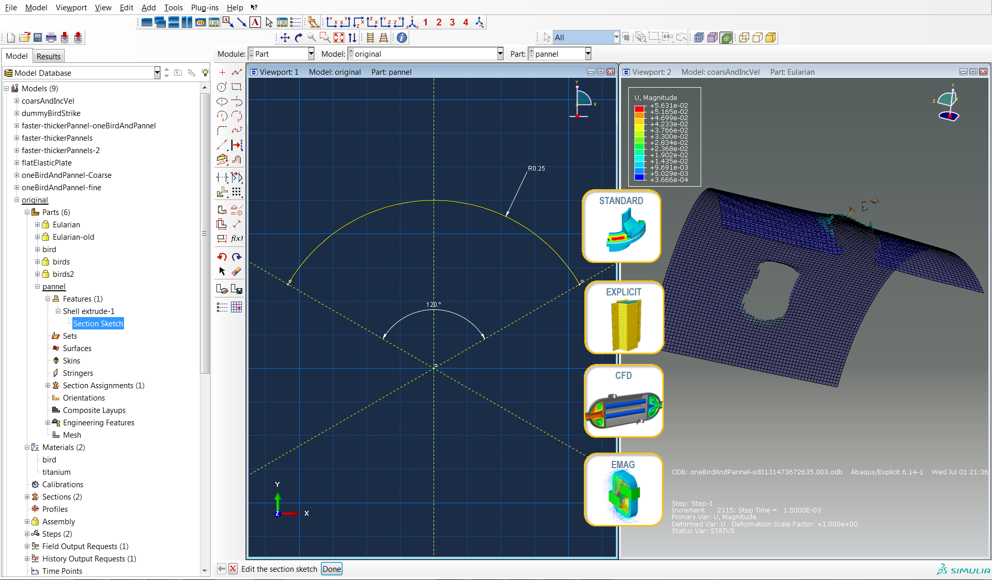

A UNIFIED & INTUITIVE INTERFACE

The realization of a multiphysics simulation, which requires the definition of numerous data of different natures, both physical and numerical, relies on a mesh, sometimes on a geometry, must orchestrate a sequential resolution or a strong coupling of physical phenomenons, and necessitates visualization of the results to understand the physics.

ABAQUS/CAE is the unified interface allowing to carry out all the actions necessary to the modelling.

- Unique, it allows to quickly find one’s reference points, because the philosophy of data setting is the same, whatever the problem treated.

- Ergonomic, it often offers several methods for doing the same thing, allowing the user to choose the solution that suits him best.

- Intuitive, it guides the implementation of the data, making it easier for the beginner to learn.

Concretely, with ABAQUS/CAE, you will be able to:

- Create / Import your own geometry

- Clean and prepare your geometry for simulation

- Mesh your geometry or import meshes

- Set up your model data: Materials, Loads, Boundary conditions, Contact and Connections

- Choose the physics you want to solve: Set up weak or sequential couplings

- Manage parallel calculation and restart,

- Import results and change analysis methods,

- Use user subroutines and scripting

- Visualize your results and export them

POWERFUL SOLVERS

ROBUST AND FAST SOLVERS

Realistic simulation is characterized by the ability to take into account complex phenomena (contact, dynamics, rupture, fluid-structure interaction, etc.). This can involve complex material behaviors (evolution of the plasticity surface, intra-laminar rupture, structural modifications linked to heat, etc.), rapid loading (detonation, impact, etc.) or instabilities (buckling).

Taking these complex phenomena into account generally results in an increase in calculation time, or even in its failure. The recognized performance of ABAQUS in solving these problems comes from the robustness of its solvers, that means their ability to integrate advanced levels of physics and to converge towards a solution.

In concrete terms, ABAQUS robust solvers give you a faster and more reliable solution.

To improve the speed of solving and to devote more time to modelling and product development, ABAQUS is particularly efficient in parallelizing calculations.

KEY FEATURES

- Intuitive data entry: Are you a beginner in finite elements? Or in ABAQUS? In multiphysics simulation? ABAQUS/CAE relies on an intelligent construction tree and a management of ordered modules to guide you from start to finish in your modeling.

- The general contact: Have you heard rumors about the complexity of defining the contact? Have you experimented with manually determining which surface pairs are likely to interact? ABAQUS detects them for you during the analysis, without increasing the calculation time.

- Material behavior: Does your material reach plasticity? Does your composite delaminate? Are you working on the crushing of porous rocks or the compression of foams? ABAQUS offers you a wide range of material behaviors that can be adapted to your needs. To illustrate the multiplicity of possibilities, here are some exotic examples of materials for which realistic simulations have been obtained: human tissues, toothpaste, sand, bones…

- Implicit/Explicit: Two solution methods do not necessarily imply two software packages. ABAQUS allows you to use both approaches depending on your applications and needs. ABAQUS even allows you to switch from one to the other when the situation requires it.

- CEL/SPH: Do you need a numerical fluid mechanics software to correctly model the evolution of pressure loading? ABAQUS integrates two methods to solve fluid-structure interaction problems in a single calculation.

- A licensing system allowing innovation: Aren’t you sure of your needs? Do you wonder which modules to choose? With ABAQUS, do not choose at the time of purchase: with a basic license of ABAQUS you have access to all the functionalities without limitation!

ADD-ONS

To meet highly specialized needs, improve the fluidity of the digital chain and accelerate complex data processing, ABAQUS also allows its users to develop and integrate custom applications. Here are some of the available extensions:

- ABAQUS Knee Simulator: This extension allows quick parameterization of knee prosthesis simulations and illustrates what can be done to customize the interface for specific needs.

- Analysis Interfaces: These extensions allow you to easily interface ABAQUS with Moldflow (plastic injection) and MSC.Adams (multi-body dynamic simulation), facilitating the transfer of information and the coupling of calculations.

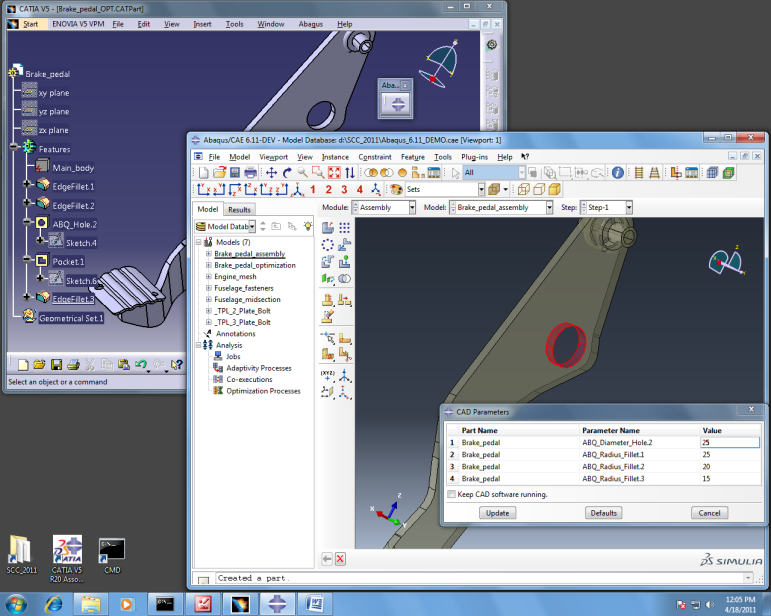

- CAD associative interfaces: Do you have specialists in CATIA, Pro/ENGINEER or SolidWorks and want to improve the transfer of information from one software to the other? These interfaces provide a two-way connection, allowing you to incorporate CAD changes without having to redo the entire data set.

- Composites Modeler for ABAQUS/CAE: ABAQUS can model composite parts, but this extension extends its capabilities, making it easier to define ply thicknesses and fiber angles, avoiding the definition of ply and structures that cannot be manufactured, reducing the risk of error and parameterization time.

- Crash Dummy and Barrier Models: These models are essential additions to speed up the generation of realistic crash test data.

- CZone: This extension allows better modelling of material crashes, allowing more accurate calculation of the forces and energy resulting from the crash.

- Geometry translators: These extensions allow the import of geometries in CATIA V4 and Parasolid formats.

- Other various extensions: Generation of 3D geometries from orphan meshes, interface for generating weld seams, definition of nuts automatically meshed in hexa…