Innovation in the Aeronautics and Defense sector drives OEMs (Original Equipment Manufacturers) to adapt in order to conceptualize, design, produce, test, certify and create new vehicles in order to be competitive. However, many companies are involved throughout the product life cycle and it is essential that they too adapt to change.

CHALLENGES: Improve communication and innovate to remain competitive

Competition

The aeronautics sector is a constantly evolving market, continually welcoming new players using new design methods with innovative technologies. The main challenge for companies in the Aeronautics and Defence industry will be to adapt to changes in the sector. They must therefore increase their productivity while maintaining quality in order to become more competitive.

Relationships with partners

The spirit of collaboration within an industry is essential. it is necessary to make the most out of global expertise and build closer relationships with customers and between different departments. The rationalisation of development practices, accessibility and data sharing are essential for the smooth running of relationships between collaborators. However, the different document formats and different software version levels make these exchanges sometimes difficult.

Innovation

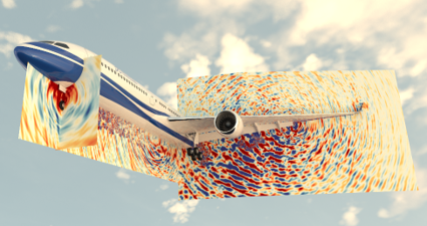

In order to meet the requirements of their customers, aerospace subcontractors will have to adopt a new way of developing, designing and testing their products. The challenge of realistic simulation is fundamental because a design error can have catastrophic human and financial consequences. The Aerospace and Defence industry is strongly impacted by the adoption of new digital solutions.

Digital manufacturing

Manufacturing planning and estimating the feasibility of support operations is an increasingly difficult challenge to overcome, with product variance increasing and technical changes accumulating throughout the program.

Integrating these design-related business lines into manufacturing and for all types of parts is a practice that aeronautics industries, whether manufacturers, systems integrators or component subcontractors, are seeking to optimize.

The development of manufacturing or assembly ranges directly within the PLM system therefore becomes an industrial practice to be mastered.

The challenge for aeronautical subcontractors is to guarantee the quality of their new products while meeting the deadlines, objectives and costs imposed on them at the same time.

Despite the use of increasingly complex components, industries must reduce their costs and meet ever more demanding demand to maintain their market share.

The optimisation of production in the Aeronautics and Defence industry will make it possible to finalise projects more quickly and thus increase margins thanks to the reduction of the design phase.

SOLUTIONS: The 3DEXPERIENCE® platform for the Aeronautics and Defence industry

PLM solutions such as 3DEXPERIENCE® are at the heart of innovation. In terms of design, simulation and production planning, the platform makes it possible to manage the relationship with your partners and principals as effectively as possible, with access to the same information in real time. The 3DEXPERIENCE® platform will save time, reduce errors, improve responsiveness, facilitate exchanges and improve production.

Having a multi-physics simulation platform capable of supporting calculations in the fields of mechanical strength, fatigue and controlling factors such as temperature and heterogeneity of the materials used is a considerable advantage to remain competitive.

By improving the manufacturing process through digital solutions, aeronautical engineers will improve efficiency, reduce development cycles and reduce waste. Offers such as Engineered To Fly will identify problems related to upstream production, while reducing the number of duplicate parts to optimise manufacturing.

OFFERS

Engineered to Fly: Improve your performance with solutions dedicated to aerospace and defence supply chain with the 3DEXPERIENCE® platform

Nowadays, suppliers face several major challenges, including:

- Better manage OEM customers’ expectations regarding deadlines and budgets

- Reduce the costs of often very complex parts

- Increase agility to meet ever-increasing demand

To help small and medium-sized businesses in the supply chain sector, Dassault Systèmes has developed solutions dedicated to the aeronautics and defence industry. These solutions allow subcontractors to gain in competitiveness while meeting the time, objective and cost constraints imposed by OEMs.

Improve your productivity and strengthen your competitiveness

Engineered to Fly is the tool dedicated to small and medium-sized companies in the aeronautical supply chain. This offer provides a whole set of dedicated tools and processes to help you face the challenges that you meet everyday and better manage the entire business process.

Fully integrated into the 3DEXPERIENCE® platform, Engineered to Fly allows all processes to be controlled in a connected way within an integrated value chain. Therefore, you can respect the deadlines, budgets and objectives set from the bids to delivery thanks to digital continuity,

Increase your productivity by 40%

With the development of air traffic, the companies in the aeronautical production chain are under pressure from major customers such as Airbus or Boeing, who ask for large volumes to be produced at a lower cost while meeting very strict delivery deadlines.

Engineered to Fly has been developed to best meet OEM’s requirements without compromising the profitability of small and medium-sized supply chain companies . This solution allows them to adapt quickly to improve their results by addressing several challenges:

- Participate in more call for tenders and better respond to them,

- Better manage the contractual relationship,

- Propose innovation while limiting risks,

- Protect the operating margin while respecting commitments,

- Organize the company in such a way as to stand out from the competition with regard to the the client’s requirements,

It is now possible for subcontractors to make better margins while reducing design times, identify upstream problems and therefore improve quality, reduce the number of duplicates and optimize part manufacturing.

The adoption of the Engineered to Fly solution allows suppliers to gain new market shares, control the production chain, increase efficiency and increase margins.

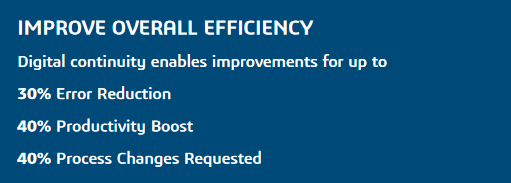

Bet on digital continuity to increase efficiency

Digital continuity across all processes provides an integrated value chain to improve business efficiency and profitability. In particular, it allows you to gain agility and optimize your performance while controlling costs.

As part of the OEM and subcontractor relationship, digital continuity is ensured through the 3DEXPERIENCE® platform, which offers a collaborative environment to simplify the development of new offers, collaborate on product development and facilitate the scale-up of manufacturing through:

Real-time project execution, management and control: from proposal to delivery

Integrated support of audit and quality processes for certification to standards or OEMs requirements.

4 STEPS TO SUCCESS

How digitalisation improves suppliers development ?

Your business requires you to face tough competition on a daily basis and several challenges such as communication with your clients, costs, production deadlines, etc.

With those 4 steps, you will be able to develop new business and improve your operations.