PART 3 – SYSTEMS ENGINEERING: THE CORNERSTONE OF A SYSTEMS APPROACH TO SUSTAINABILITY Frugality and restraint in practices, energy consumption and raw materials is one…

DIGITAL CONTINUITY WITH SIMULATION ACTS AS A CATALYST FOR SUSTAINABLE INNOVATION

PART 2: DIGITAL SIMULATION TO REDUCE INDUSTRY’S ENVIRONMENTAL FOOTPRINT Product performance, limiting the number of physical prototypes, digital simulation is being used in many…

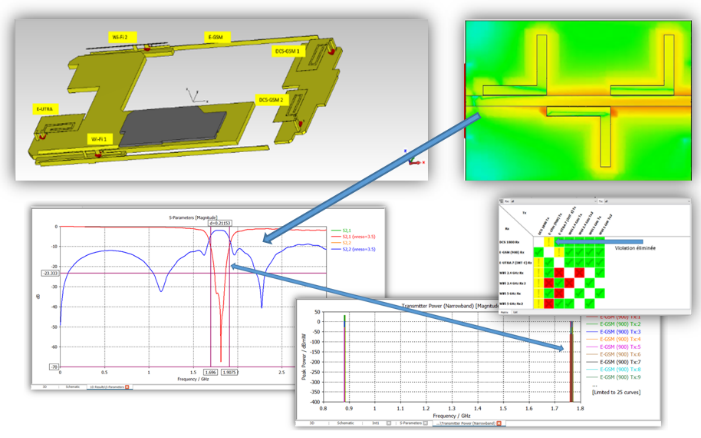

Interference mitigation between co-site cell phone antennas with CST Studio Suite®

Did you know that a 5G smartphone has more than eight antennas, which together with other factors create interference to be mitigated? The radios and…

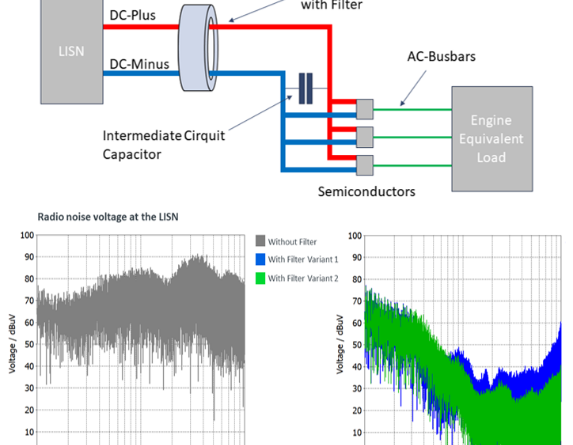

Modular EMC-Simulation In/With the System

Have you passed the electromagnetic compatibility (EMC) test of an electric motor with the international standard requirements? If you have difficulty in setting up a…

NUCLEAR ENERGY FOR A RESPONSIBLE FUTURE WITH THE 3DEXPERIENCE® PLATFORM

On the occasion of the World Nuclear Exhibition (WNE), dedicated to the civil nuclear sector, held in Paris from 30 November to 2 December 2021,…

AUTOMOTIVE INDUSTRY: NEW DIGITAL CHALLENGES

CENIT-KEONYS organizes its digital INNOVATION DAY, an emblematic event around the latest digital technologies in the industry on March 23, 2021. The day will focus…

READY TO?

Every year, the CENIT-KEONYS group organizes its INNOVATION DAY, an emblematic event around the latest digital technologies in the industry. I invite you to register…

AEROSPACE AND DEFENSE: NEW DIGITAL CHALLENGES

CENIT-KEONYS organizes its digital INNOVATION DAY, an emblematic event around the latest digital technologies in the industry on March 23, 2021. The day will focus…

A FRUITFUL PARTNERSHIP BETWEEN CENIT AND GXP CONSULTING SWITZERLAND

Or how to combine digital technologies and value-added consulting to boost innovation in the life sciences industry (focusing on Medical Devices) The life sciences industry…

Digital transformation: A performance booster for manufacturing industry

Interview with Jean-Luc BADOC, VP CoE DELMIA, Apriso & Ortems Global Services, Dassault Systèmes “Digital technology allows industry to change course as needed, while continuing to…

Systems engineering to better understand complex systems design

Why opt for a Systems Engineering approach in industry? Technological changes are accelerating today at an unprecedented speed to give place to digital technologies. Human…

THE CLOUD IN INDUSTRY: THE INNOVATION BOOSTER FOR MID-SIZE COMPANIES

What if collaborative innovation became the real driver of your growth and competitiveness? Cost reduction, quality and innovation are the main challenges the industrial…

How to deploy PLM on the Cloud in the industry?

More and more SMEs, ETIs and start-ups are using Cloud services to design, simulate and plan their industrial production. Like private interactions, the industrial world…

LOUIS ARMAND HIGH SCHOOL IN THE CLOUD, GUARANTEE OF A SUCCESSFUL DIGITAL EDUCATION

Louis Armand High school in Nogent sur Marne, close to Paris, can be proud to be one of the first schools to opt for Dassault…

DIGITAL ACCELERATION BOOSTS 3DS OUTSCALE

No break during lockdown for this SecNumCloud certified sovereign Cloud actor since December 2019. The acceleration of digital uses in many sectors has even boosted…

Through advanced planning and scheduling systems, manufacturers take the digital path.

Digital manufacturing is now concerning all the industries, from the stationary and diary sector to the production of PVC and thermoplastic elastomer pieces. In order…