Louis Armand High school in Nogent sur Marne, close to Paris, can be proud to be one of the first schools to opt for Dassault Systèmes’ 3DEXPERIENCE® platform on the Cloud. With convincing results, particularly during lockdown, for its students in mechanical engineering, who had all the online teaching tools to coordinate their projects in CAD and digital simulation. KEONYS gives you the exclusive testimony of Frédéric Xerri, Associate Professor in Mechanical Engineering, in charge of the Industrial Product Design classes.

“It is through collaboration and the contribution of all talents that we will be able to solve the challenges of the post-crisis and, more generally, of the 21st century.”

Train students to the latest digital technologies in industry is the mission of Louis Armand High school, which offers general, technological and professional pre and post-baccalaureate trainings. This academic starts in 2015 a European collaborative project on the theme of robotics involving its students in sophomore classes dedicated to the design of industrial products. The success of this pedagogical innovation very quickly highlighted the benefits of the cloud thanks to the online and real-time collaboration of all the players of a project.

KEONYS – How did Louis Armand High school organize during the period of lockdown? What about ongoing projects and educational follow-up?

Frédéric Xerri – We immediately set up an efficient system for our students on the 3DEXPERIENCE® platform. The students did not encounter any methodological problems when working remotely since we were already using the platform as a training tool before lockdown.

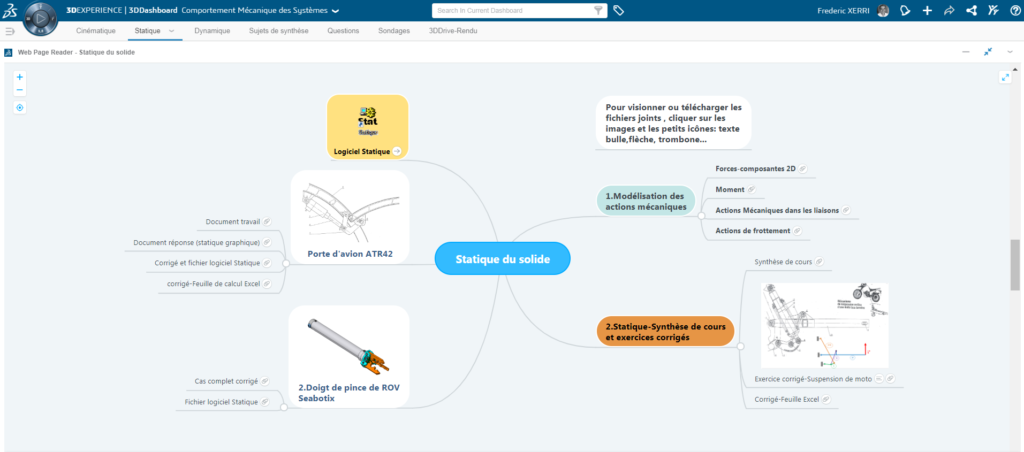

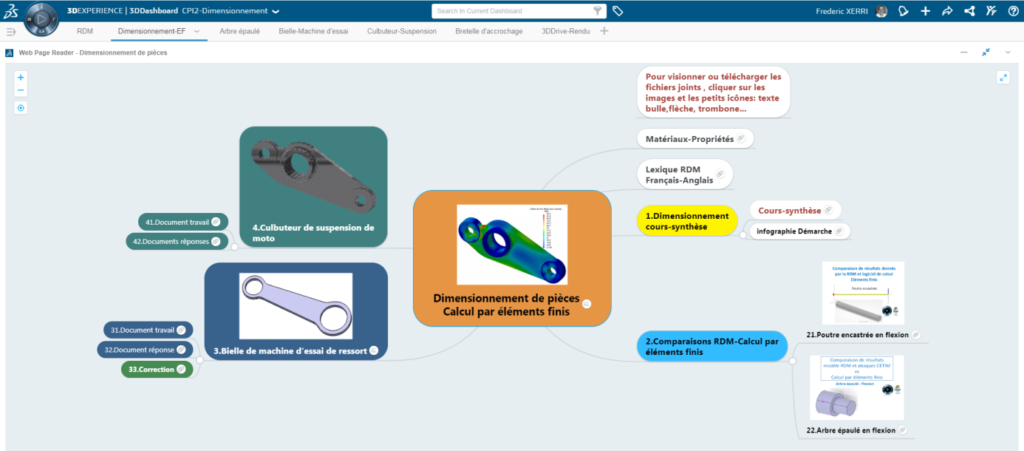

However, we did not need to waste time in developing and monitoring our courses. We made all the course materials available to them in structured dashboards on the platform. The 3D Dashboards allow the integration of pedagogical and professional web applications that we were using before lockdown, as mental maps to access the graphical visualization of a whole course and its contents: summaries, useful links, files to download…

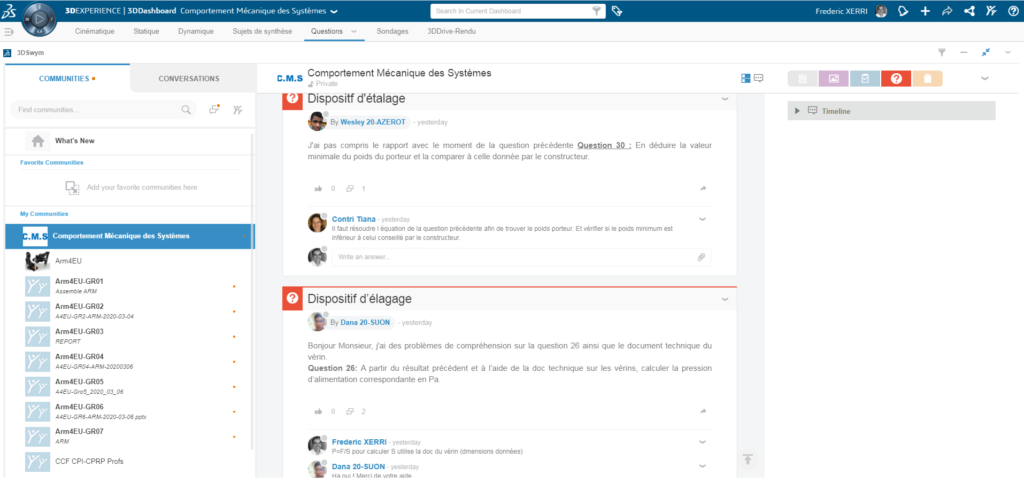

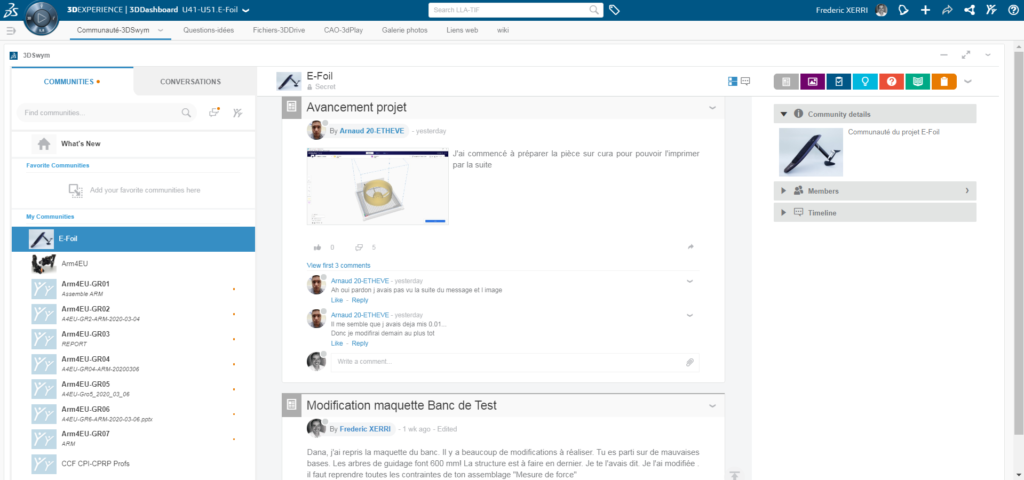

The use of a community dedicated to the course allows for constant and ongoing interaction with students. Answers to questions from some of them benefit everyone.

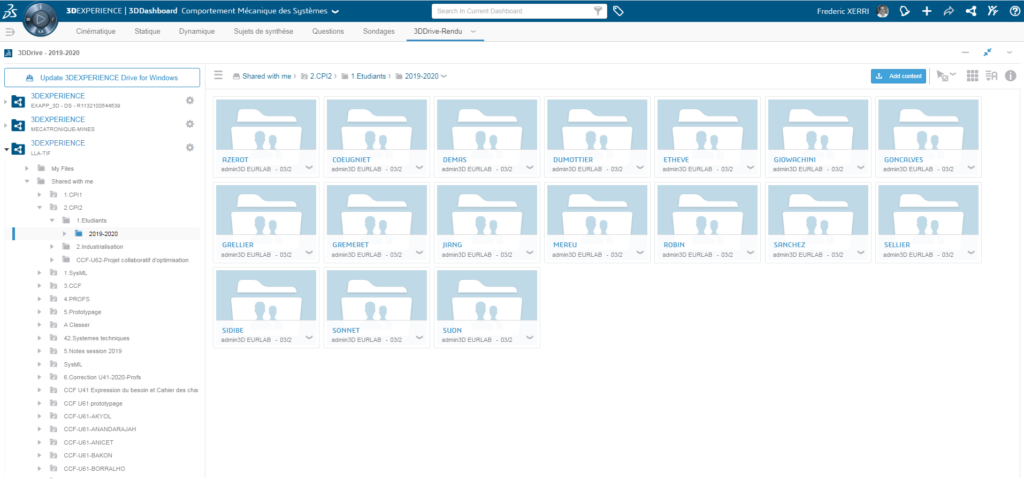

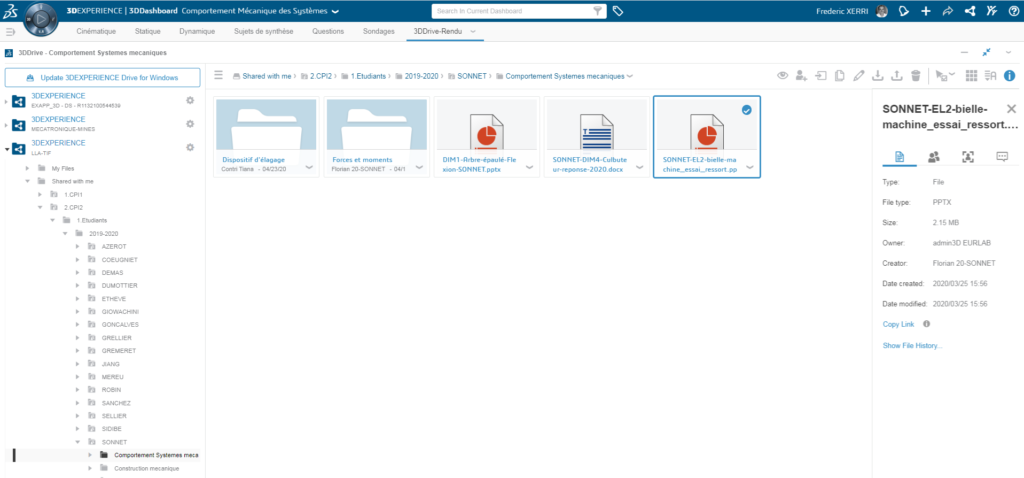

The students render their work on a 3D Drive, a kind of Google Drive integrated into the platform.

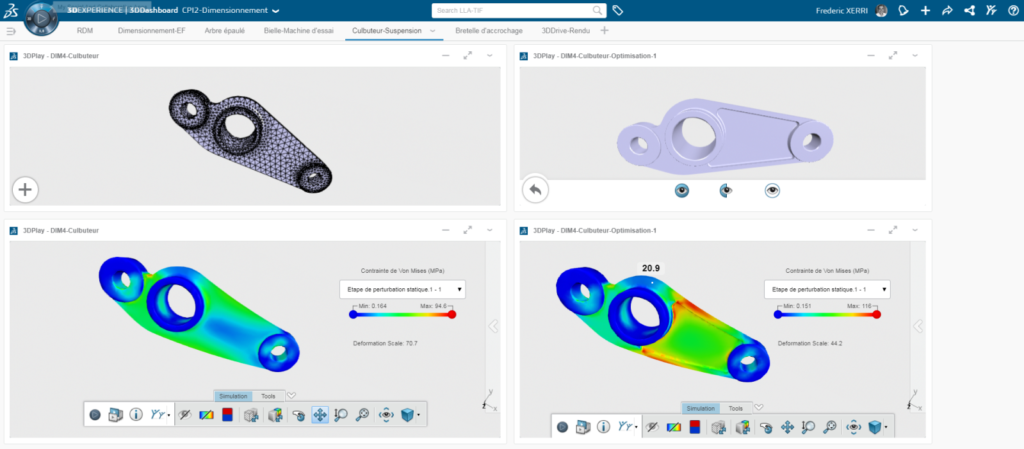

3D Dashboards also allow remote monitoring of design projects thanks to the use of integrated CAD visualization tools and the contribution of communities dedicated to projects.

The 3D Dashboards are a source of permanent enrichment for the successful completion of a design project.

KEONYS – Can you already measure the positive impact of cloud use?

F.X. – The 3DEXPERIENCE® platform on the Cloud allows our students to save time and gives them flexibility for better exchanges. They used to use several platforms and multiply the number of softwares (for product creation, simulation, file repository…). Today, they mix collaboration systems with creation and simulation tools. The entire project is centralized and integrated into a single application available online.

The real-time collaborative aspect is a differentiating feature with very high added value. The continuous link between teachers and students but also between students, who chat, exchange and co-create via their PC, Mac or smartphone, has even generated during lockdown an amplifying effect in terms of agility and efficiency to bring new ideas to life.

KEONYS – How the practical work went?

F.X. – The activity has never stopped. We continued to give them homework remotely. The courses I gave by videoconference are a complement in the form of a synthesis.

All the CAD data is centralized on a single platform and continually updated. We use structured catalogs containing parts and assemblies that allow us to do design and simulation work. For those who had problems carrying out simulations, the results were visible in 3D Dashboards with the possibility of interaction to interpret the different results.

KEONYS – Were all students properly connected to the platform?

F.X. – Most of them had access to the 3DDashboards through a web browser. We had a solution for those who faced some problems to do CAD or simulation; they could connect to the 3DEXPERIENCE® platform on the remote controlled high school stations which have more resources than their PCs. All of their work was stored in the cloud and therefore visible and accessible by everyone at all times.

KEONYS – What did this period of lockdown inspire you in pedagogical and societal terms?

F.X. – Periods of crisis highlight problems and amplify them.

In the educational world, students and teachers who did not make sufficient use of collaborative practices before lockdown have found themselves destabilized or even lost to continue working at a distance.

The teaching of collaborative work has to be integrated very early in school learning as it will influence human behaviour. As for collaborative work platforms and tools, they are an additionnal to foster collaboration and innovation.

Technical tools for collaboration have been around for a long time and are constantly evolving. But their proper use cannot be improvised. Those who used them before the crisis caused by the Covid-19 had no difficulty working, except for a few internet speed problems due to the exceptional number of simultaneous connections.

My colleagues from BTS Industrial Product Design and I are delighted to have been able to ensure the pedagogical continuity of the training without too many problems thanks to two major factors: a very strong investment in national and European collaborative work for the last fifteen years and the use of the 3DEXPERIENCE® platform on the Cloud for more than five years.

I hope that the lessons of this crisis will be translated into a considerable change in educational practices from an early age to raise awareness and demonstrate the positive values of collaboration. It is through collaboration and the contribution of all talents that we will be able to solve the challenges of the post-crisis and, more generally, of the 21st century.

|

Information about Louis Armand High school / BTS Industrial product design |

| Activity: train sophomore technicians in the design of industrial products with a mechanical focus.

Number of students: the High school has 1000 students and 150 teachers, including 48 students and 4 teachers in the Sophomore Industrial Design section. Key date: 2015, they are the first academic users of 3DEXPERIENCE® on the Cloud. Location: Nogent-sur-Marne (France) KEONYS solution used for design and data sharing: 3DEXPERIENCE® on the Cloud. Number of users of the solution: 100 per year. |