The factory of the future, digital factory, digital factory, or factory 4.0… the terms are numerous to speak of modernization of the industrial tool. These evolutions are made possible thanks to new key technologies such as IoT, big data, artificial intelligence, or augmented reality

And at the same time, tomorrow’s plant is much more than technology. It is a different way of organizing work to optimize its production process and anticipate hazards. So technology is a tool, but what key organizational needs does it address?

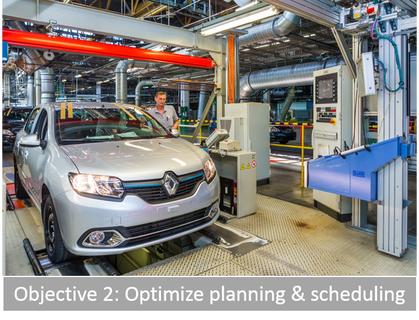

Your objective n°2 : Optimize production planning and scheduling

What’s at stake?

How to reorganize my production and optimize it to manage the daily incidents of a factory: men, machines, raw materials, subcontractors,…

How’s it going today?

When an SME operates without tools, people are dedicated full-time on certain scheduling tasks. Everything is done on EXCEL, under pressure and with a risk of errors far too high.

There are so many variables to organize the production that only the computer can quickly optimize it and simulate scenarios ” What If? “, but in the end it’s always a human brain that makes the decision. Franck Eichenberger, Business Development Manufacturing at KEONYS

Tomorrow, how will it be?

The employee will be able to make better trade-offs, using a scheduling and decision support tool. As soon as a customer order arrives, the software solution will allow the best planning of the means (machines and human resources). The manufacturing instructions will be sent in real time to the operators.

The benefits?

Finally, EXCEL files, card tables, pressure, etc. are replaced by a decision support tool that optimizes planning according to constraints, to reduce the risk of errors and increase responsiveness.

Before, we had a linear production line with a process A followed by a process B, C, D, etc. Today, thanks to these new technologies, we are able to move on to more complex logics. This is the plant of the future: the permanent adaptation of its production process. It therefore presupposes that upstream and downstream, tools and skills are developed to analyse this production process.

Anaïs Rajery-Rasata, SME & ETI Accelerators Manager – Bpifrance