Every year, the CENIT-KEONYS group organizes its INNOVATION DAY, an event showing the power of digital technologies in the industry. Jos Voskuil, the “Virtual Dutchman, ” a great expert in PLM for more than 25 years and Founder of PLM consulting company TacIT, carried out the customer interviews. We asked him about his feedbacks and his vision of the evolution of digitalization in product development processes.

KEONYS: Who is the “Virtual Dutchman” in the real life?

Jos Voskuil: The Virtual Dutchman is a fortunate guy who started as a physics teacher focusing on science and soccer. Now I am a person curious about human behavior, not only in businesses but also in society, and physically I transformed into a (hobby) racing cyclist to stay fit.

This transformation was possible thanks to my life as a Flying Dutchman, training and mediating in all kinds of PLM engagements worldwide. Thanks to all the travel, which I regret a little now, due to our need for a sustainable future, it brought me insights into how important it is to understand cultural differences. The science teacher tries to define everything without emotion; the Virtual Dutchman has learned the importance of emotion, even in business.

This transformation was possible thanks to my life as a Flying Dutchman, training and mediating in all kinds of PLM engagements worldwide. Thanks to all the travel, which I regret a little now, due to our need for a sustainable future, it brought me insights into how important it is to understand cultural differences. The science teacher tries to define everything without emotion; the Virtual Dutchman has learned the importance of emotion, even in business.

KEONYS: How was this passion for PLM born?

Jos Voskuil: Actually, in my first commercial job, I led a data management group, and I had a background in programming, so I was pretty excited when implementing SmarTeam in 1996 – a windows-based system extraordinarily flexible and customizable. When I began my private company TacIT, I was planning to focus on knowledge management.

However, I was dragged back into SmarTeam thanks to my friends in Israel. With the acquisition of SmarTeam by Dassault Systèmes, I suddenly got global exposure to PLM implementations worldwide. Thanks to my implementation experience and connection with SmarTeam R&D, I became responsible for industry templates and mediation in the field whenever there was a topic to solve.

This was such an exciting role, meeting people all around the world and working with them towards a positive outcome. It was continuous learning for me. I realized that PLM is also so much about people, expectations, and methodology before even discussing the technology. This really became my passion. Understanding and learning what motivates an organization to move forward with PLM – why and how – before connecting to the system integrators.

KEONYS: What changes in the adoption of digital tools have you observed in recent years?

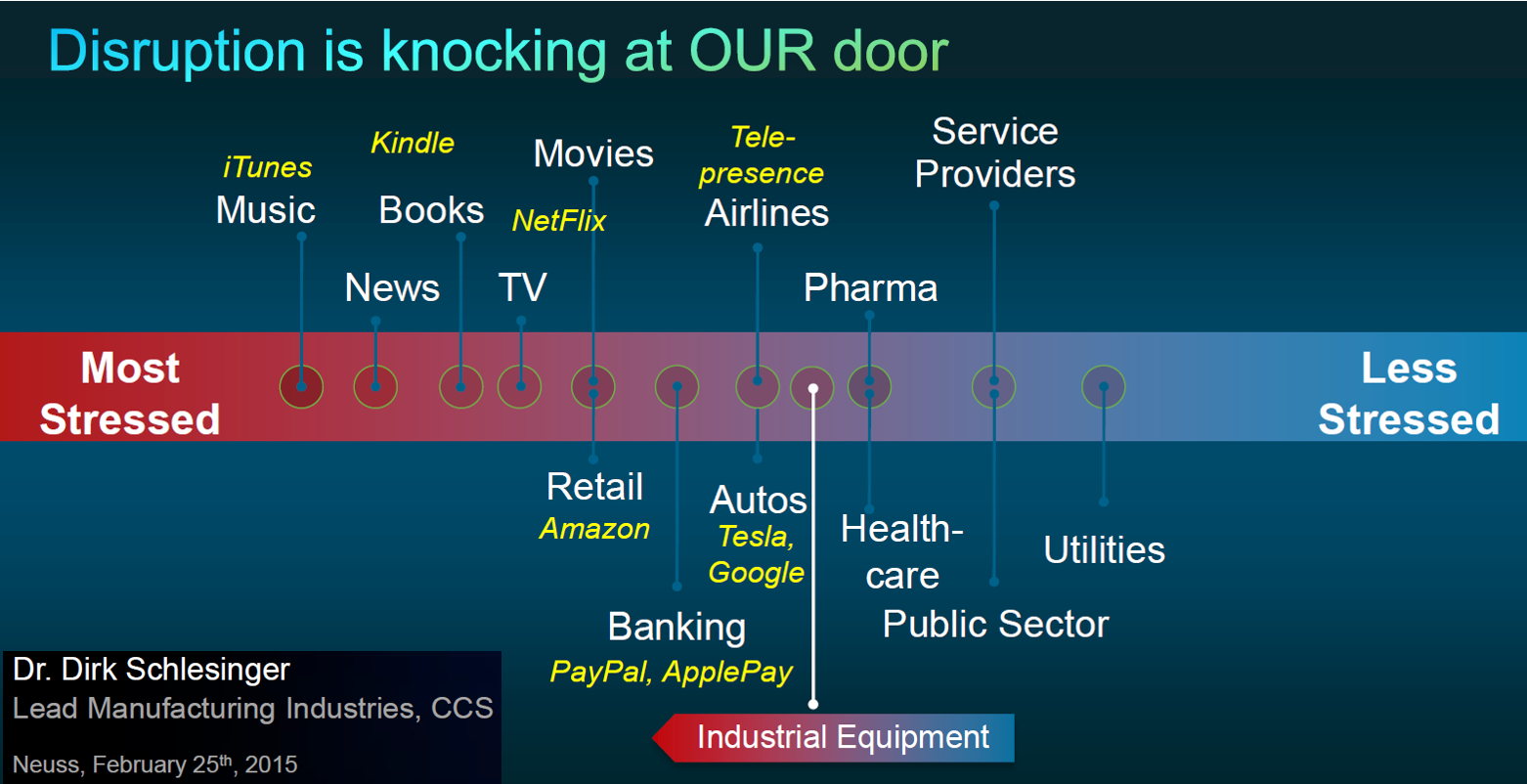

Jos Voskuil: The main change I see is that there are not many pro-active companies that can disrupt themselves. A big part of the disruption now comes from new companies with new business models. They do not have a legacy to maintain. Research shows that many traditional companies spend most of their R&D money on improving their current product portfolio incrementally instead of investing in innovative ways to sell their products.

Or what we hear more and more, deliver a specific outcome as a service. Suppose you are selling “outcome as a service”. In that case, you need to have a good end-to-end understanding of the product’s performance, potential flaws and costs, usage by the customer while remaining competitive in pricing.

If your business has not yet been disrupted, that might be the case when there is not too much competition or that the margins are still too high. I believe we will see a serious disruption coming from all kinds of sustainable initiatives. For example, pumping up more oil to get more revenue will probably no longer work due to environmental taxes. Investing in new and efficient energy sources will be the future. Are the traditional oil companies able to do this? If not, goodbye.

KEONYS: What did the 15 European customer interviews for the Innovation Day inspire you?

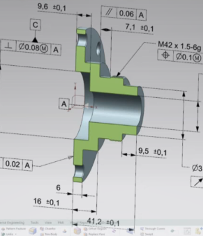

Jos Voskuil: What I liked the most was that every person had a passion for their products. I challenged them where possible on sustainability, new ways of working and often related to a model-based definition approach. The model-based definition, Dassault Systèmes calls it 3DMaster, is, in my opinion, a way of working, mandatory to have an efficient connection between engineering and manufacturing. As we do not want people to created derived files like drawings separately from the Model. Besides the overhead of creating drawings, it leads to errors because people have been working on a wrong version of the Model.

Jos Voskuil: What I liked the most was that every person had a passion for their products. I challenged them where possible on sustainability, new ways of working and often related to a model-based definition approach. The model-based definition, Dassault Systèmes calls it 3DMaster, is, in my opinion, a way of working, mandatory to have an efficient connection between engineering and manufacturing. As we do not want people to created derived files like drawings separately from the Model. Besides the overhead of creating drawings, it leads to errors because people have been working on a wrong version of the Model.

And if you talk about Industry 4.0, there should be at the foundation a model-based approach. There is a direct connection between engineering and manufacturing data based on the 3D Model. I found it interesting that many of the persons I interviewed were optimistic about a model-based approach. Technology was not the issue; the human factor (people & process change) and legacy were often the reason preventing a full deployment. I got inspired by learning that these people in the field see and experience the value of 3D connectivity.

And if you talk about Industry 4.0, there should be at the foundation a model-based approach. There is a direct connection between engineering and manufacturing data based on the 3D Model. I found it interesting that many of the persons I interviewed were optimistic about a model-based approach. Technology was not the issue; the human factor (people & process change) and legacy were often the reason preventing a full deployment. I got inspired by learning that these people in the field see and experience the value of 3D connectivity.

Now it has to bubble up more to the higher management layers.

KEONYS: Did you notice a different degree of digital maturity between startups, SMBs and big companies?

Jos Voskuil: That is hard to say. I would state that startups are for sure not interested in their digital maturity. They want their (minimum viable) product out to the market, a.s.a.p. for the early adopters. Their challenge is to be well connected to their early customers and measure where to improve. Using sensors in your products combined with other IoT capabilities will enhance direct visibility of a product’s performance and bring a higher digital maturity.

Small and Medium Business often started from a successful product(line) years ago. They have an excellent reputation for quality or specific capabilities. They often lack the resources and time to analyze their own performance and potential business in the next five to ten years. This is where you see the most significant risk of not jumping on the digital highway on time. Excel, for example, is often the tool connecting people within different disciplines. Not a system as this is considered as an overhead and takes time to implement.

Small and Medium Business often started from a successful product(line) years ago. They have an excellent reputation for quality or specific capabilities. They often lack the resources and time to analyze their own performance and potential business in the next five to ten years. This is where you see the most significant risk of not jumping on the digital highway on time. Excel, for example, is often the tool connecting people within different disciplines. Not a system as this is considered as an overhead and takes time to implement.

Finally, related to the big companies, you will be surprised how traditional they are still in the PLM domain. Often because data based on the ERP system become the dominant information consumed at the board level. How do we operate? What does our margin develop itself (against competition)? It is harder to get these numbers from innovation processes. Where should we invest time and resources even when the outcome is not directly clear?

In that sense, SMBs and Startups are much closer to their customers. I think big companies can learn from startups and sometimes from SMBs how to work in a multidisciplinary approach. See also my (short) episode of the PLM Doctor is IN: PLM and Startups.

KEONYS: Sustainability is increasingly integrated into the world of industry. How can digitalization help to combine ethics and profitability?

Jos Voskuil: Digital transformation is an opportunity to make industrial and societal issues coincide. As a company, you need to have end-to-end processes and performance visibility in place. When designing new products or services, companies should look at the total lifecycle costs and their products’ impact on the environment. This can be much better done in modern virtual environments, where you can simulate the virtual products and operations models’ performance.

As it is not only about 3D models when I talk about models. Weather predictions are based on models, and we keep on improving them. Now, scientists worldwide are learning to build and fine-tune Covid-19 models to have the best countermeasures: the better these models, the less suffering and the expensive waste of people and resources we have.

I hope that besides governments, more and more investors and consumers start to push for more sustainable processes and solutions. And here comes ethics and profitability. For example, suppose we understand the impact of meat consumption on the environment. In that case, we might be willing to pay double or triple for the same steak. This extra money could then stimulate farmers and companies for innovative solutions.

KEONYS: The pandemic crisis underlines the European dependence on the “factories of the world”. How can digitalization help industries to reinvent themselves?

Jos Voskuil: There should be reverse thinking about the factories of the world. We use them because they are cheap, and they create an environmental impact in their country for our benefit. When Europe becomes accountable for its remote environmental impact, it might be more efficient to produce locally again. Perhaps not as cheap, however, with less risk of disruption. Like in nature, we should go back to a diversity in models, allowing us to prioritize one over the other, depending on circumstances. There is so much to gain here. For that, we need digitalization to simulate, monitor and analyze performances. It is the real digital thread we need.

KEONYS: What is your vision of the adoption of digitalization in the industry for the next decade?

Jos Voskuil: I think from my previous statements, it is clear we must digitalize our industries if we want to remain profitable and competitive. Environmental pressures in all sectors will push companies to innovate. If you do not innovate, you will be disrupted, either fast in industries close to consumers or slow in industries close to governments. The next ten years are the most critical years for the planet. I believe digitalization will help us speed up required innovations in all its aspects IF it does not become a monopoly for the happy few.

KEONYS: How to look together in the same direction?

Jos Voskuil: A difficult question to answer. Humanity has no desire and experience to go all together in the same direction. COVID-19 is the first test for global collaboration. To survive globally, a “my country first” way of thinking already disturbs the union – everyone wants to claim success. For me, the best way to be optimistic about the future is to make sure education and science information are available for everyone. We should not believe in miracles.